Raw denim is denim in its original state —unwashed, untreated. No distressing, no chemicals, no pre-fade.

Origin : Japan

Selvedge denim was once the standard, woven on shuttle looms throughout the early 20th century. By the 1950s, demand for denim exploded, and manufacturers turned to projectile looms. These machines could produce fabric five times faster and nearly twice as wide—50–60 inches compared to the 30 inches of shuttle looms. As a result, selvedge nearly disappeared from mainstream production.

In Japan, however, shuttle looms were never abandoned. Mills in Okayama Prefecture preserved and refined the craft, not only out of nostalgia but from a commitment to fabric quality and variety.

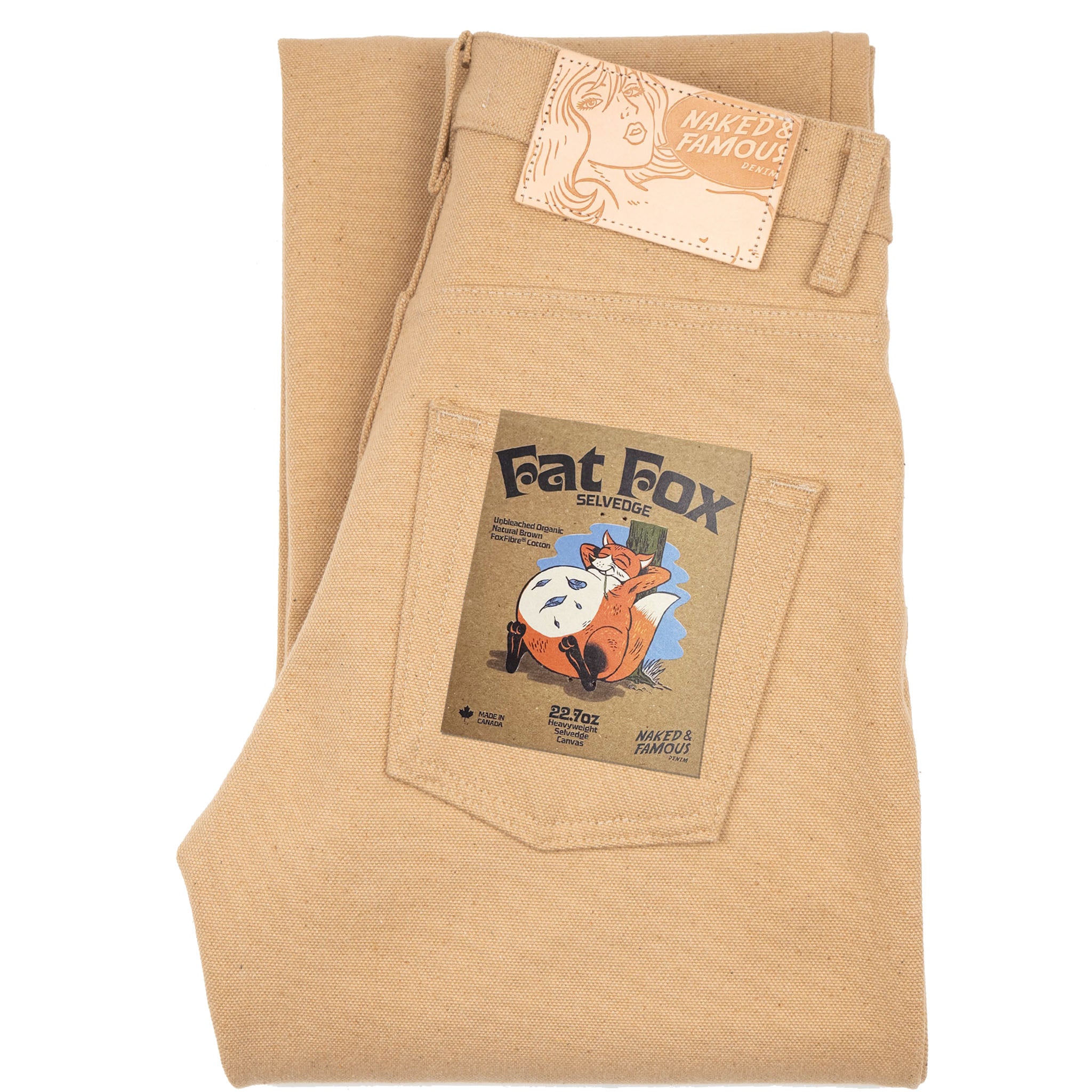

At Naked & Famous Denim, we travel to Japan multiple times each year to work directly with mills in this region. These collaborations result in exclusive, small-batch denims—ranging from ultra-heavyweight and highly textured fabrics to experimental blends like cashmere, milk, linen, fun-innovative glow-in-the-dark or scratch-and-sniff denim, and so much more. For us, it always starts at the source.

shuttle looms

Shuttle looms—like the original Toyoda machines still operating in Japan—work differently from the wide, high-speed looms used in mass production today. Instead of firing individual weft yarns across the warp with air or projectiles, shuttle looms carry a small wooden shuttle back and forth. Each pass lays down a continuous strand of yarn, interlacing with the warp and sealing the edge of the fabric as it goes.

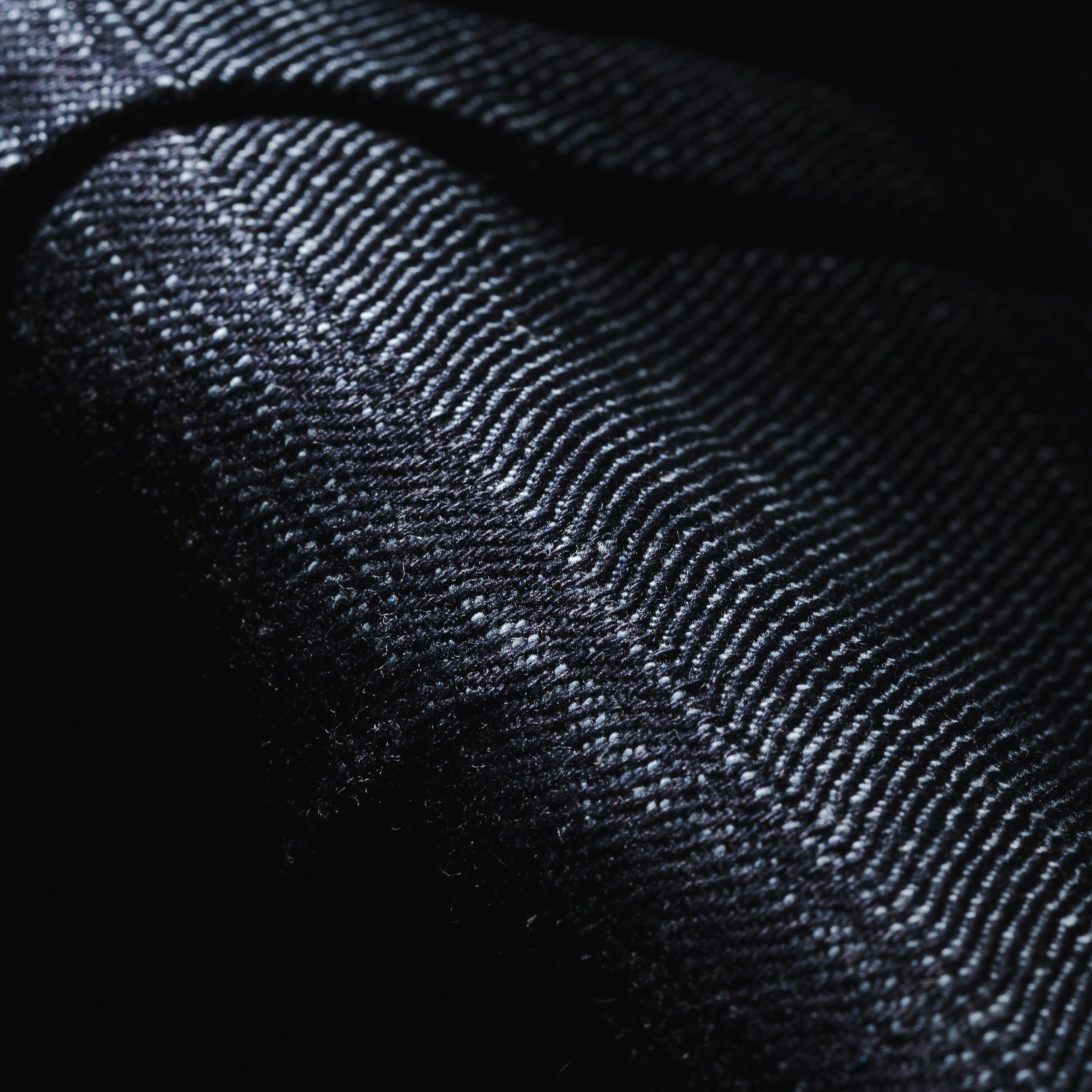

The process is slower, noisier, and more variable—but that’s exactly where its value lies. Because shuttle looms weave under lower tension, the fabric often develops subtle irregularities: slubs, yarn shifts, and surface texture that can’t be replicated on modern industrial looms. The width is narrower, usually around 30 inches, and the result is a self-finished edge called the selvedge. Far from decorative, it’s structural proof of traditional shuttle weaving.

Because shuttle looms weave under lower tension, the fabric often develops subtle irregularities: slubs, yarn shifts, and surface texture that can’t be replicated on modern industrial looms. The width is narrower, usually around 30 inches, and the result is a self-finished edge called the selvedge. Far from decorative, it’s structural proof of traditional shuttle weaving.

Indigo

Rope dyeing is the most labor-intensive method of indigo application, perfected by Japanese mills. Warp yarns are batched into thick ropes and passed through towering machines that dip them into indigo baths, then lift them back up into open air to oxidize. This dip-and-oxidize cycle is repeated many times to build the desired shade.

Unlike vat dyeing, which fully saturates the fibers, rope dyeing only dyes the outer layer of each cotton yarn, leaving the core white. As the surface indigo wears away over time, the white interior is exposed—this contrast is what produces raw denim’s signature fades.

Selvedge

Product of shuttle loom weaving—a tightly finished edge that prevents fraying and defines the full usable width of the fabric. Nowadays, it’s also a clear indicator that the fabric wasn’t mass-produced on high-speed, wide-width looms. If there’s a selvedge, it means the denim came from a traditional, narrow shuttle loom—machines that operate slowly, under low tension, and require more setup and operator involvement.

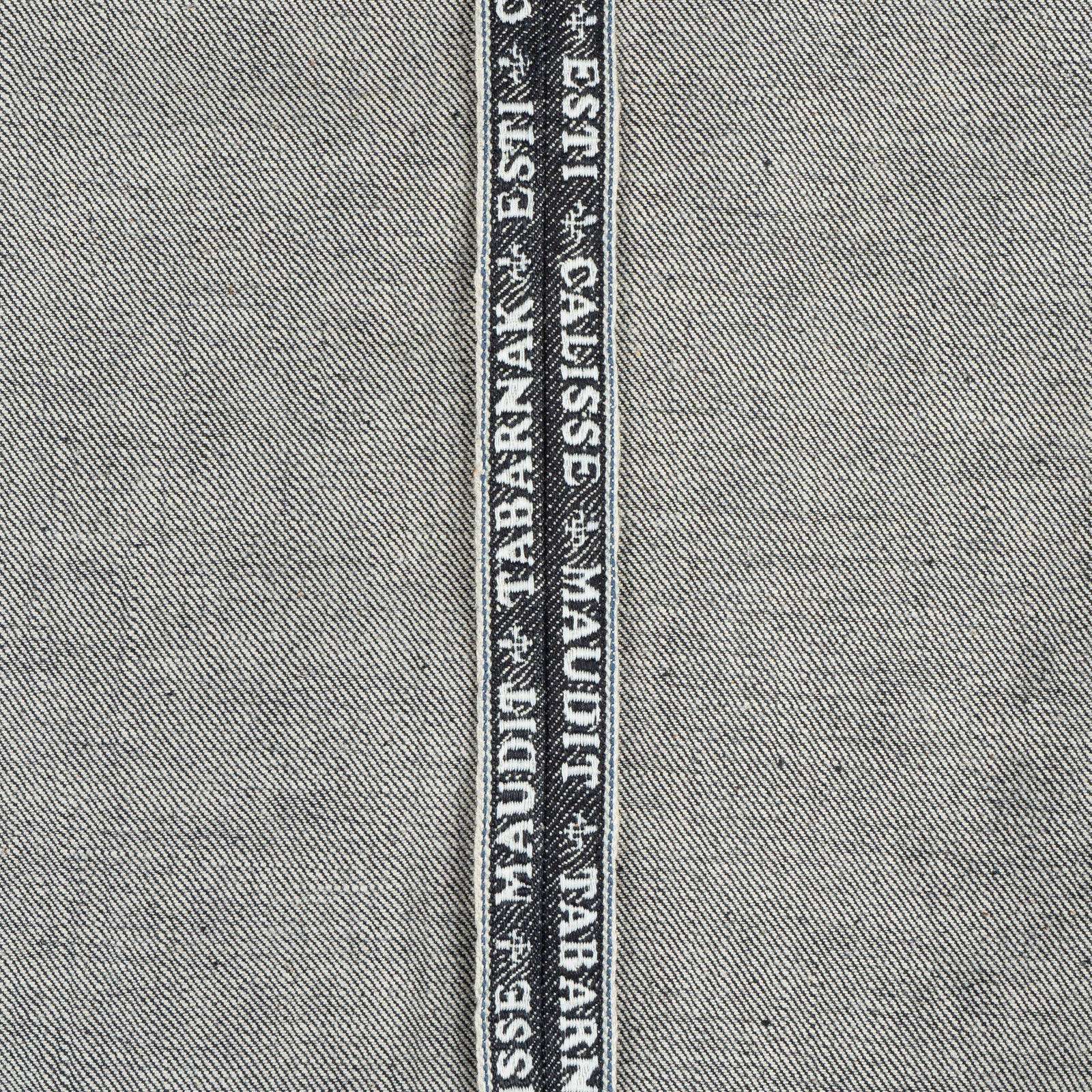

Historically, mills identified fabrics for different customers by using colored lines in the selvedge, most famously red. Today, the selvedge ID is also a creative detail. At Naked & Famous Denim we’ve played with green, orange, pink, glow-in-the-dark, rainbow, and yes—a few with curse words woven right into the edge. (Go ahead, roll that cuff and raise a few eyebrows. We dare you.)

It’s one of the few places on a finished pair of jeans where the production method remains visible and we love it.

treatments

Even raw denim isn’t completely untouched. After weaving, most fabrics go through finishing treatments that prepare them for cutting, sewing, and long-term wear. These steps don’t erase the “raw” status — they simply shape how the fabric shrinks, how seams behave, and how the surface feels. The most common are sanforization, anti-skewing, and singeing. Learn more below ➝

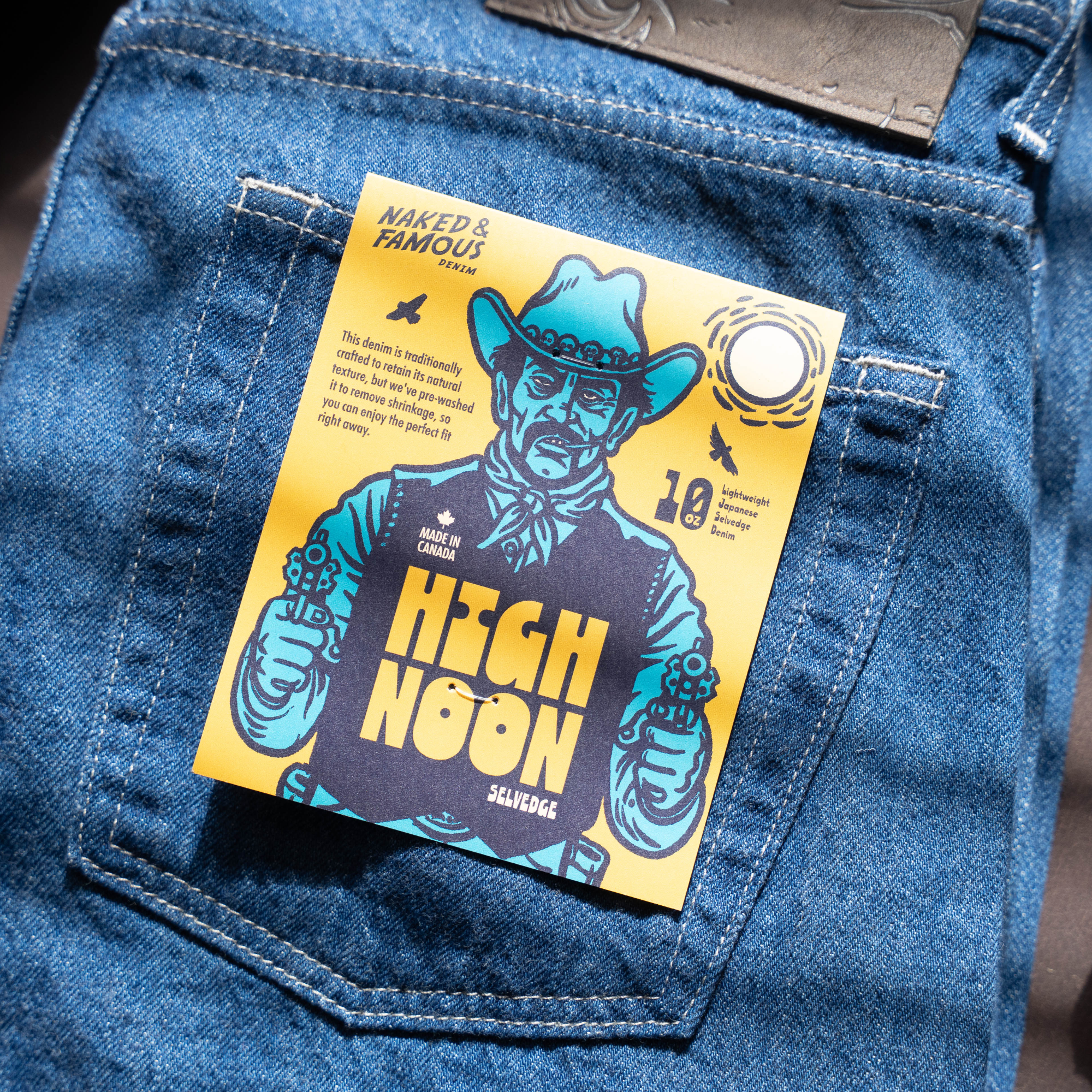

Sanforization is a mechanical pre-shrink process invented in the 1930s by Sanford L. Cluett. In this treatment, the fabric is moistened, stretched, and then compressed against a heated rubber belt and cylinder to stabilize it. The process ensures that most shrinkage happens before sewing. Sanforized raw denim keeps its raw, unwashed character but will shrink only about 1–3% after the first wash, while unsanforized (loom-state) denim can shrink up to 10% and usually requires a hot soak before wear.

➝ Most are sanforized unless specifically noted as unsanforized.

For example, the High Noon Selvedge is unsanforized and then given a single rinse.

Denim twill naturally contains torque—an angular tension built into the weave—that can cause the legs to twist after washing. Anti-skewing offsets this by rotating the fabric slightly in the opposite direction during finishing.

➝ Anti-skewing is applied to most of our denims. However, some unique or experimental weaves can’t undergo this process.

For example, the Revival Frankenstein alternates between left-hand and right-hand twill every few inches, which makes it incompatible with anti-skewing. Over time the fabric naturally develops leg twist.

After weaving, denim often retains small, fuzzy fibers that stick out from the yarn surface. Singeing is a finishing step where the fabric is passed quickly over an open flame, heated copper plates, or gas burners to burn away these protruding fibers without damaging the cloth. This process leaves the fabric cleaner, with sharper twill definition and deeper color, ensuring that the unique yarn structure and dye qualities take center stage rather than being obscured by lint or fuzz.

➝ Most are singed unless specifically noted.

For example, the Flying Squirrel Selvedge is intentionally not singed, keeping its naturally hairy surface intact.

Every pair of our jeans is cut, sewn, and finished in Canada. It’s how we’ve always done it, and how we’ll keep doing it. All of this work happens in our own factories, where skilled teams handle every stage of construction. The result combines Canadian manufacturing with premium Japanese selvedge denim sourced from some of the world’s best mills.

Wear. Fade. Repeat.

A brand new pair of Weird Guy in Natural Indigo Selvedge stands on the left; on the right, the same jeans after months of wear.

Before

After

fades explained

Denim is one of the few materials—along with leather—that gets better the longer you use it. Raw denim doesn’t just wear down; it adapts. Creases, fades, and tears form in response to your lifestyle, turning the jeans into a record of how you live. Pre-distressed jeans miss that connection, since their fades are placed on a fit model’s body and rarely match your own. Raw denim evolves with you, not for you.

With wear, common fade patterns emerge:

- Whiskers: Horizontal creases at the hips and front pockets from sitting and walking

- Honeycombs: Angular stacks behind the knees from bending

- Stacks: Abrasion at the hem where excess length bunches above shoes

- Thigh fades: Smooth wear across the front thighs from movement and friction

- Train tracks: Parallel lines along the outseam and inseam from fabric rubbing

denim weight categories

Denim weight refers to the weight of the fabric per square yard, measured in ounces. It’s determined by the thickness of the warp (vertical) and weft (horizontal) yarns, as well as the density of the weave. Different weights affect comfort, durability, and break-in time.

Soft and easy to wear from the start. Great for warmer climates or year-round comfort if you want jeans that break in quickly.

The most versatile range—durable but still comfortable once broken in. Works well across all seasons and balances strength with wearability.

Rigid, dense, and built for endurance. These jeans take commitment to break in but reward you with high-contrast, dramatic fades.

In 2025 we launched the Super Heavyweight 40oz - The World's Heaviest Denim Jean. An extreme benchmark in denim—stiff, punishing, and guaranteed uncomfortable.

→ See the 40 oz jeans

Washing your jeans

Our jeans are made from raw, unwashed denim—you get to decide their fate. The more you wash them, the softer and paler they become. The less you wash, the longer they hold their rigid feel and deep indigo color.

There’s no strict rule for when to wash. Some people wait months to maximize contrast, others wash regularly. The real answer: wash them when they’re dirty, smell, or you’re just ready.

How to Wash

- Turn jeans inside out and fasten the fly to avoid abrasion.

- Use cold water to reduce indigo loss

- Add a small amount of mild detergent if needed.

- Soak in cold water for an hour then rinse for a gentler option.

- Always hang dry or flat dry. Never tumble dry.

- Wash separately, as indigo may bleed (a process called crocking). Keep white clothes and furniture away until fades settle.